Related Blogs

Explore more with our related blogs on our products, manufacturing processes, solutions and more.

All you need to know about the different types of crash barriers

Ensuring safety for traffic movement on highways and road systems is a challenging task. With accidents increasing at an alarming rate each day, road safety becomes inevitable. Empowering roads with proper safety barriers help minimise the extent of risk and damage to vehicles and passengers by absorbing the impact energy during accidents. This is where the need for a crash barrier arises.

Crash barriers actually serve as the safety measure for motorists, pedestrians preventing roadside hazards. While most of the people might think as simple fences that prevents vehicles going off the roads and highways, but they are highly engineered and have five major advantages that are listed below:

Enhancing Safety on the Roads:

These barriers are used to protect traffic from hazards such as steep slopes, sharp bends, etc. that might otherwise cause rollover crashes. Crash barriers are designed to increase the safety on roads and highways. They also prevent vehicles from entering opposite lanes thereby lowering the risk of dangerous crashes.

Help in Minimizing the Impact of Collisions:

Generally, during a highway collision, the vehicle tends to go sideways. The tires of the vehicle go and hit the barrier which then redirects the vehicle back onto the road. This phenomenon often helps in minimizing the damage to the vehicle.

Need Very Less Maintenance:

In comparison to other forms of road safety barriers, crash barriers need very less maintenance. Designed with robust engineering, the crash barriers can withstand high impacts.

High Visibility:

Accidents on highways mostly during night time when the visibility is low. The crash barriers were made with metal and highly visible even during the night. Thereby very effective in avoiding accidents and also prevents vehicles from going off the road.

Strong and Durable:

Made tough, the crash barriers can withstand harsh weather conditions and last for as long as 30 years and more.

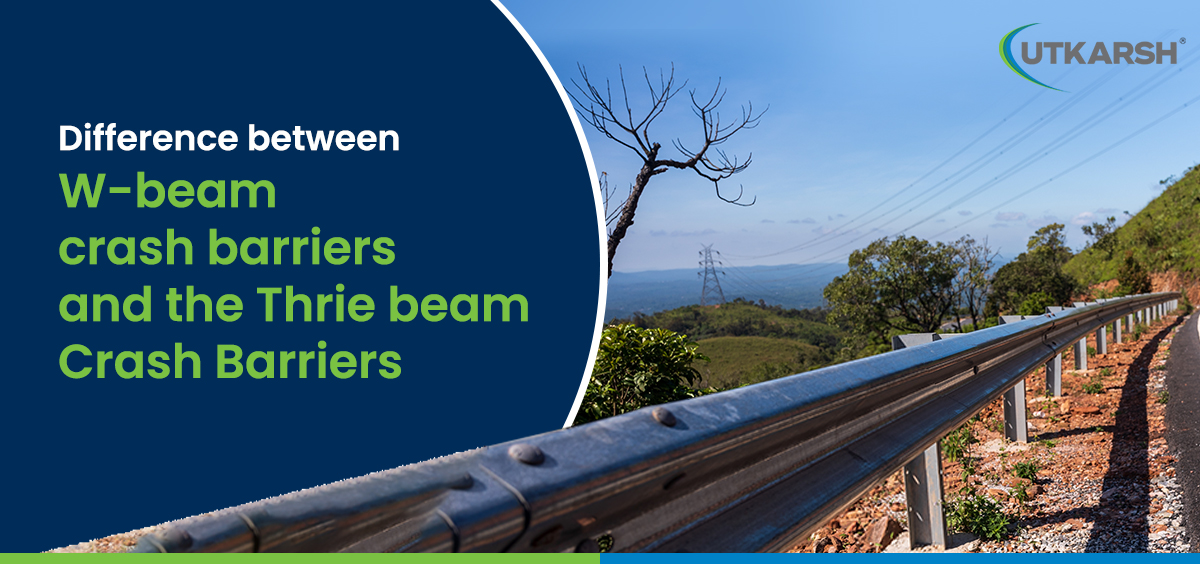

Based on shape, size and components used, there are two types of crash barriers for highways. They are the W-beam and Thrie-beam Crash Barriers. These can be categorized into:

- Single sided crash Barrier

- Single sided Double beam crash Barrier

- Thrie-Beam single sided crash Barrier

- Double sided single W Beam Barrier

- Single sided Thrie-Beam crash barrier with End section

- Single sided crash barrier with End section

| Types | W-Beam: | Thrie-Beam: |

|---|---|---|

| The Specialties | Economical | High on performance |

Versatile | Ideal for reduced deflection | |

Ideal for high impact resistance | High resistance | |

Durable | Apt for speed traffic | |

Economical |

While selecting the best crash barrier, the following factors should be kept in mind:

- The installation requirement

- The flexibility of the chosen barrier

- The barrier terminal treatment

- The required length

- The transition of one type of barrier to another

In addition to keeping these factors in mind, the barriers should always conform to the International specifications like AASHTO M 180 Guardrail, Euro norm (EN 1317–1&2), Indian Road Congress Standards (IRC), etc. If the product adheres to these norms, it is assured that they are manufactured with high grade quality of raw materials that provide superior strength and stability.

What makes HDPE Pipes better for Agriculture and Irrigation Application?

HDPE pipes are flexible plastic pipes that are mainly used for industrial and agricultural sectors to transfer fluid or gases. These are the perfect replacements for age old concrete or steel pipelines. Made from high-density polyethylene, these are highly impermeable. This quality makes it suitable for high pressure pipelines.

HDPE has multiple applications. They find use in water and gas mains, sewer mains, rural irrigation, fire system supply lines, drainage pipes and many more. These pipes can be melted, reformed which makes it rugged, flexible and long-lasting.

Due to some inherent features, HDPE pipes are best suited for agriculture and irrigation applications. The toughness and resistance to strong chemicals and their resistance to corrosion are some of its major features. They along with factors like low weight, cost-effectiveness and durability have contributed to its ever growing need.

HDPE pipes can be bent on site to a radius twenty-five times more than a normal pipe at or below 20 degree centigrade of ambient temperature. This feature leads to major cost savings. On the other hand, because of their high impact resistance and flexibility, they are suitable to be installed in soils that also include earth-quake prone areas. HDPE pipes ensure very high flow. Unlike ferrous piping solutions, these do not develop rust or corrode. Hence, these never affect the flow capabilities by building up internal resistance while fluids or water pass through them.

You May Like: Highlighting The Difference Between CPVC and UPVC Pipes

No piping fatigue: HDPE pipes are outstandingly fatigue resistant. Unlike plastic pipes, they are capable of handling the occasional and recurring surge of water flow that is very common in water distribution systems. These pipes are ductile but they are not rigid.

No water loss: HDPE pipes are leak-free joints. While other piping systems are highly susceptible to water leakage due to the types of joints that they use, HDPE pipes can be joined by heat. This results in permanent leak free joints that help us save our most precious resource.

Convenient installation: The flexibility of HDPE pipes, along with their tensile strength , makes the perfect choice for trenchless installation. This technology helps them in getting installed under the river, lakes, ponds, creeks with minimal public disruption.

High durability: HDPE pipes do not corrode or rust. This extends their life and results in long term cost savings. With a service of ranging from 50-100 years, HDPE pipes become the ideal solution depending on usage, installation and project design.

Environment –friendly: Apart from the above mentioned physical attributes, HDPE pipes have minimal impact on the environment. They do not emit hazardous levels of toxins even during the manufacturing process. Also, these can be easily recycled back into non-pressure piping applications.

The outstanding performance of HDPE pipes ensures that consumers get clean and safe potable water. While other pipes have high chances of having leaks that lead to more usage of electricity to process and pump water, HDPE ensures zero leak. This reduces the need for electricity which in turn helps the consumers in saving utility costs. These, together, make HDPE the ideal choice for agricultural and irrigation applications.

Solar Energy Is The Age of Renewable Power

We live in the age of Automation

and Artificial Intelligence. Whatever electronics we buy, we demand it with

high energy or long-lasting battery backup. When it comes to energy, solar is

something which strikes our mind as it is the most sustainable power

alternative. According to Allied Market Research, the solar energy market

accounted for $52.5 billion and is estimated that it will reach $223.3 billion

by 2026.

The Sun emits enough power onto Earth to satisfy all the human energy demand. Solar energy is a kind of energy which is readily available and renewable, and that is why it is an attractive source of energy. During the early times, solar energy harvesting has been quite expensive and relatively inefficient. But with the advancement of technologies in the last two decades, has increased the usage of solar energy in this generation by decreasing the costs and increasing solar panel efficiency.

The use of solar energy has come

a long way now. This year, the world has witnessed more than 115 Gigawatts of

solar installation across the globe, which is quite more than all other

generation technologies combined together. In the next few years, technological

improvements will ensure that solar power becomes cheaper than ever. It is

predicted that by 2030, solar will become the most important source of energy

for the production of electricity in many parts of the world.

The recent surge in the demand of

solar panel installation in rooftop and rapid adoption in the architectural the field is the significant drivers which have led to the rise in demand for solar

cells. Moreover, recent technological advancements have significantly boosted

the adoption of solar panels in order to generate electricity.

With the increase in the demand for

solar cells, we can expect a tremendous increase in the use of solar panels in

the future. It can capture more light and transform the light energy into

electricity. The consumers, as well as producers, are more likely to adopt

solar energy if it produces the kind of energy which is equal to other

non-renewable resources. This will also have a positive impact on the

environment and climate change.

Given the fact that solar panel

is so easy and quick to install and also flexible. It can be used to power

something as small as a toy or as large as a city. Solar energy has a bright

future and solar installations will continue to grow over the coming decade.

At Utkarsh, we understand the essence of renewable resource solutions through which a sustainable approach in

everyday living can be adopted. Utkarsh India, being the leaders in solar

lighting, offer street light poles with mounts for solar panels that are

engineered as per your customization.

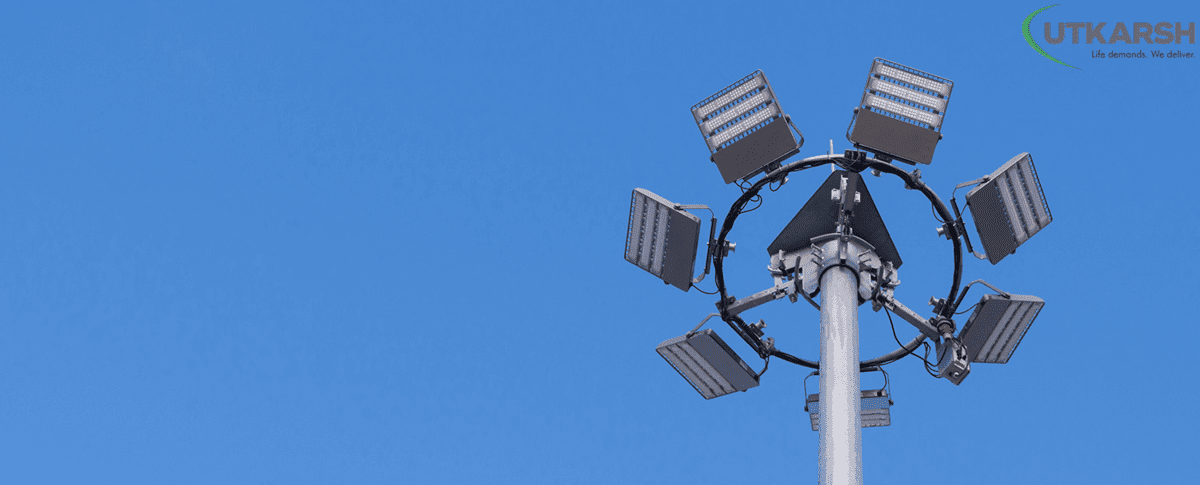

Applications and Benefits of Using High Mast Lighting

High Mast Lighting Systems, also known as HMLs, are usually used to provide light to large areas like large warehouses, shipyards, highways, parking lots, stadiums, etc. High mast lights are usually installed on 40ft-150ft tall poles and four to six lights are installed on each pole. High mast lighting is one of the most preferred ways of illuminating big areas. These lights are mounted on considerable heights to illuminate large areas uniformly.

Common Advantages of High Mast Lighting Systems

· Energy Costs – It is quite obvious that large areas require a higher light output to illuminate the entire area uniformly. Itis true that high mast lighting solutions conventionally use lamps or halogens of high wattage which leads to an increase in electricity bills. But with the introduction of LEDs, the energy cost has gone down considerably. This is because LEDs prove to be more cost and energy-efficient in the long run.

· Maintenance cost – High mast LED lighting brings down the maintenance cost as they have a longer life. The lifetime of good quality LED fixture is usually more than 50,000 hours.

· Lighting Performance - The lighting performance is one of the crucial parameters that you need to consider before deciding on buying a high mast lighting system. High mast LED lighting systems provide great illumination, don’t emit heat or infra-red light and consume less electricity which makes them energy efficient as well.

What makes Utkarsh India one of the leading high mast lighting pole manufacturers in India?

Utkarsh India offers a wide range of High Mast poles, which can be customized as per client requirements. The poles are manufactured conforming to IS Standards and can withstand wind speed up to 300Kmph. Here are some of the factors which makes us a premier high mast light pole manufacturer in India –

· In-house design facilities (Structural &Foundation) with PLS/Special Software (Validate from IIT-Kharagpur)

· Available in three-point as well as two-point suspension.

· Rust-free electroplated rope drum, sprocket and torque limiter.

· Rope drum of the winch has one left hand and another right-hand groove for better alignment of the ring

· Available in both detachable arm and fixed armLantern Ring.

· 7 tanks galvanising process for better adhesion and uniformity.

· All testing facilities are available in plants including Spectrometer for chemical analysis.

· All Trailing cables conform to IS 9968 (P-1) for safety and durability.

· All the hardware supplied is stainless steel which ensures a better life.

· Our head frame has a stainless steel axle with an anti-rotation clamp to prevent damage to the axle and stainless steel guide roller for smooth rolling of cable and rope.

· Heavy-duty drive chain (1/2 inch pitch) for lifting the ring.

· We provide safety locking rope for high mast safety.

· We provide double safety protection of motor(one mechanical and one electrical)

· Optionally, we provide an anti-theft nut for foundation bolt with a specially developed wrench for High mast.

· HDPE buffer arrangement for Lantern Ring.

· All winch & motor tested with proper load before dispatch.

· Structural design is checked for all orders before production.

· Wind tunnel test is conducted from IIT-Kanpur.

Utkarsh India, being a leading high mast light pole manufacturer in the country, we have supplied our products to Indian Railway, National Highway, Refineries and Oil Sector, Military Engineering Service, Steel Plants, etc.

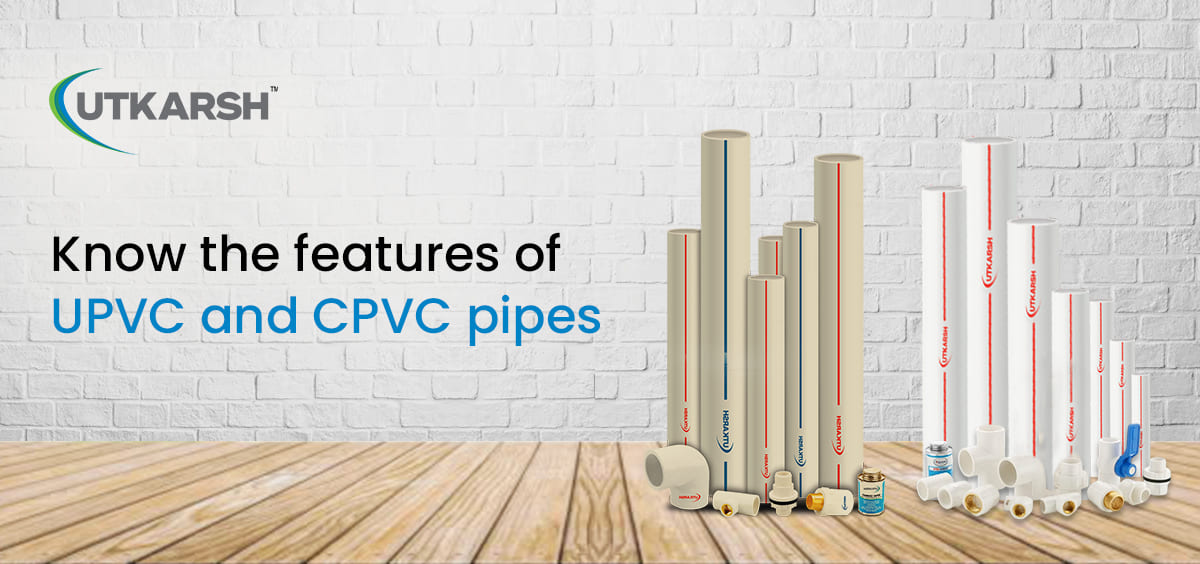

Highlighting The Difference Between CPVC and UPVC Pipes

Poly Vinyl Chloride (PVC) is one of the most widely produced and used synthetic polymers. Plasticizers are added during the manufacturing of PVC in order to make it easy to bend and to increase its flexibility.

Well, PVCs are also manufactured without plasticizers in order to make it rigid and sturdy. This material is known as UPVC. SometimesPVC is treated with chlorine using free radical chlorination in order to obtain PVC.

What is UPVC?

Unplasticised Polyvinyl Chloride, commonly referred to as UPVC other than its full form, is rigid PVC, lacking any plasticiser. Renowned for its resilience, UPVC stands as a tough, sinewy, transparent, and durable material, exhibiting resistance to atmospheric influences, moisture, and various chemicals. It boasts excellent electrical properties and low flammability. Globally, UPVC pipes and fittings are widely embraced, known for their inherent rigidity and resistance. UPVC pipes, recognised for their durability, fire-resistance, and recyclability, epitomize a reliable choice in diverse applications worldwide.

You May Like: What makes HDPE Pipes better for Agriculture and Irrigation Application?

What is CPVC?

Chlorinated Polyvinyl Chloride (CPVC) is manufactured by the chlorination of PVC polymer. Due to the chlorination, it acquires some unique properties like flexibility and the ability to withstand extreme temperatures. It is due to its chlorine content that it has excellent chemical resistance, primarily to acids, alkalis and salts, and is therefore ideal for the chemical process industry.

Application of UPVC Pipes

UPVC(Unplasticised Polyvinyl Chloride) pipes and fittings provide the perfectsolution for cold water applications across diverse sectors, includingresidential plumbing, swimming pools, industrial process lines, food andbeverage industries, saltwater lines, and the chemical sector. Utkarsh India’sUPVC pipes are rigorously tested through six stages of quality checks, ensuringboth reliability and high performance. This cost-effective, low-maintenanceproduct is especially suitable for domestic cold-water transportation systems.

Application of CPVC Pipes

Utkarsh India’sCPVC (Chlorinated Polyvinyl Chloride) pipes are versatile and ideal for variousapplications. They are perfect for both hot and cold water systems inresidential spaces such as homes, apartments, hotels, resorts, hospitals, andhigh-rise buildings, ensuring a pure and hygienic water supply. Additionally,CPVC pipes are well-suited for water mains in both domestic and industrial settings,as well as industrial water lines and plant piping. They offer excellentchemical resistance, making them suitable for use in industrial lines.

Difference between CPVC and UPVC

Delve into the CPVC vs UPVC comparison and gain valuable insights to make well-informed decisions tailored to your specific industrial applications and requirements.

| UPVC | CPVC |

| UPVC does not contain any plasticizers | CPVC is composed of plasticizers |

| UPVC is not bendable | CPVC is bendable |

| UPVC pipes are not suitable for carrying high-temperature liquids. | CPVC pipes are ideal for carrying high-temperature liquids |

| UPVC is not used for the purpose of drinking water transmission. | CPVC is suitable for the purpose of drinking water transmission. |

| UPVC is rigid | CPVC is flexible |

Final Note

PVC, a widely utilised material in pipeline production, comes in two distinct types: UPVC and CPVC. The critical difference lies in their composition, UPVC is made without plasticisers, while CPVC involves the addition of plasticisers and a chlorination process. When evaluating temperature resistance, CPVC surpasses UPVC in its ability to withstand higher temperatures. As a leading CPVC and UPVC pipe manufacturer in India, Utkarsh India stands out with their offerings.

Here are some top features of Utkarsh India's CPVC and UPVC pipes, aiding in the decision-making process for those who want to know:

CPVC pipes

· Corrosion-resistance

· Bacteria proof

· Chemical resistance

· Fire safety

· Leakproof

UPVC pipes

· Lead-free

· UV resistant

· Chemical resistant

· Waterproof

· Pressure resistant

Uses And Advantages of HDPE Pipes

High-density polyethylene is a thermoplastic polymer which is produced from the monomer ethylene. The high-density polyethylene pipe market is growing rapidly in India. As per many trusted reports, the HDPE pipe industry in India was at $99.9 million in 2018 and it is estimated to reach a staggering $233.5 million by 2026.

HDPE pipes are known for their high tensile strength, flexibility, durability and lightweight. These pipes have been used for municipal and industrial water applications for several years. The fact that HDPE pipes are environment friendly makes it even more favourable. These pipes are non-toxic, chemical and corrosion resistant, and ensure a long lifespan. The best quality HDPE pipes from top HDPEpipe manufacturers and suppliers ensure zero leak rate.

Here are some of the properties of HDPE pipes -

· HDPE pipes can resist many solvents, chemicals, and acidic environments

· HDPE pipes have high strength and flexibility and are much lighter in weight.

· These pipes are resistant to impact and that is what makes it a favourable choice for large industrial projects.

· Superior quality HDPE pipes from leading HDPE pipe manufacturers have a long life span of 50-100 years

Related: What makes HDPE Pipes better for Agriculture and Irrigation Application?

Advantages of HDPE pipes –

· Easy to handle and hassle-free to install – HDPEare easy to handle and install. Its density is way lesser than steel and does not demand any heavy lifting equipment during the time of installation. As these pipes are flexible, they can be bent easily.

· Minimized installation costs – These pipes require fewer fittings and can be welded into seamless leak-free pipe runs. This reduces the expense of labour and installation.

· Corrosion and chemical resistance – One of the finest quality of HDPE pipes is that it features chemical and corrosion resistance. It offers brilliant corrosion resistance to corrosive, acids, bases and salts and remains unaffected by fungi and bacteria.

· Heat-fused joints - HDPE pipes are heat fused to form a strong joint. This offers significant installation advantages when compared to traditional pipes.

Conclusion

At Utkarsh India, we are one of the leading HDPE pipe manufacturers and suppliers in the country. Our HDPE pipes have been tested and proven effective for aboveground, surface, buried and floating applications. Our HDPE pipes are popularly known for their applications in water supply, potable water distribution, sewage transportation, sprinkler irrigation systems and so on.

What makes our HDPE pipes an ideal solution are the standards that we maintain at Utkarsh India.

· IS 4984 - 2016 for Water Supply

· IS 4427 for Potable Water

· IS 14333 for Sewerage

· EN 12201 for Water Supply

· IS:14151 (Part I & II) for sprinkler irrigation systems

How Does Railway Electrification Work?

The purpose of the railway electrification system is to supply electric power to trains and trams. Electricity is typically generated in large and relatively efficient generating stations, transmitted to the railway network and then distributed to the trains. Power is supplied to moving trains with the help of a continuous conductor running along the track in the form of an overhead line or a third rail which is mounted at track level. Electrified trains feature quicker acceleration, reduced fuel costs, emit less amount of CO2 and are much lighter, meaning they create less impact on tracks.

Railway electrification structures are used in Indian Railways as a powerful measure to achieve cost-effectiveness. Electric-powered trains have a number of advantages over diesel engines –

· As per many trusted reports, electric traction is cheaper by about 45% for freight traffic and about 47% cheaper for coaching traffic when compared to diesel traction. Electric trains can save energy by regenerative braking while diesel engines need to consume energy when stopped.

· Electrical traction can use solar and wind energy sources. Regenerative energy that is produced in Three-Phase Electrical rolling stock during the braking of trains, results in saving in energy consumption by about 30%. In a study conducted by The Energy and Resource Institute (TERI), electric traction is about three times more energy-efficient when compared to diesel traction.

You May Like: Applications and Benefits of Using High Mast Lighting

· Maintenance costs of electric lines may be on the higher side, but many systems claim lower costs due to reduced wear-and-tear because of the lightweight of the trains.

· Electric traction improves the throughput and section capacity by about 15%, as it enables haulage of heavier freight and longer passenger trains at a higher speed.

· Electric traction is more economical and plays a crucial role in improving the operating ratio.

Conclusion

Utkarsh India is one of the leading manufacturers of railway electrification structure. Weare a Core Part I approved vendor to manufacture and supply all type of Railway Electrification structures like portals, masts, beams, gantries, small parts steel, sub-station structures and customized structures as well.

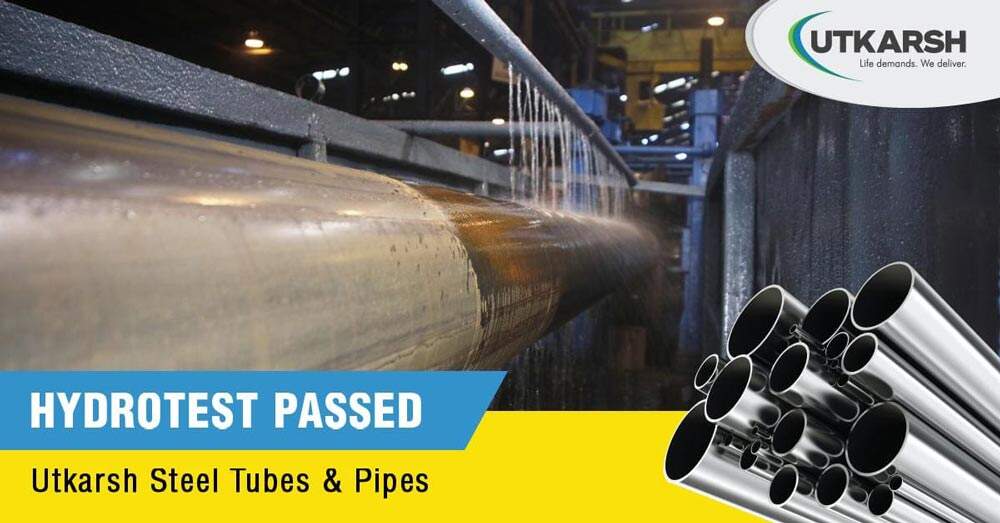

A Complete Overview of MS Pipes

Mild steel pipes or MS pipes are used for the purpose of plumbing, firefighting, heating, ventilation and air conditioning. These pipes are perfectly suitable in several industries and various engineering applications.

These pipes are manufactured using low carbon (less than0.25%) steel and that is the reason why they do not harden and are hassle-free and easy to use. MS pipes can also be welded to various shapes and sizes for the purpose of pipelining and tubing.

These pipes are usually coated with metals, paints, varnish etc. to prevent it from rusting under extreme condition and make them long-lasting and durable.

Here are some of the salient Features of MS Pipes –

· They feature high tensile strength and are extremely sturdy

· Contains a low percentage of carbon

· It can be easily welded

· Easy to fabricate and readily available

· Best quality MS pipes ensure around 100 years of lifespan

· Budget-friendly

MS pipes are widely used for structural and mechanical purposes, general engineering, domestic applications, water steel pipes, fencing, etc.

You May Like: Highlighting The Difference Between CPVC and UPVC Pipes

What makes UtkarshIndia one of the leading MS pipe manufacturers in India?

Utkarsh India’s MS Pipes conform to national and international standards and are duly approved by all National/InternationalInspecting & Certification Authorities like SGS, CE, DNV, BVQI, TUV and more. We manufacture MS Pipes in various sizes, grades and specifications which meets national and international specifications. The raw materials of MS Pipes are procured from Kobe SteelLtd., Nippon Steel and JFE Steel located in Japan.

Our superior quality MS pipes are highly demanded in the sectors of agriculture, oil and gas, public health, housing, irrigation, engineering etc. We also export our products to Australia, Africa, France, Oman, China, Austria, Nepal, Uruguay, etc.

If you are looking for superior quality MS pipes, please get in touch with us. We supply our clients with MS pipes at a nominal cost with the best quality standards.

Everything You Need To Know About Submersible Pumps

A submersible pump, as the name suggests, is a kind of pump that can be fully submerged in water. It pushes the water to the surface by converting rotary energy into kinetic energy into pressure energy using. It does so with the help of a motor. The motor is hermetically sealed and close-coupled to the body of the pump.

One of the major advantages of submersible pumps is that it does not need to be primed because itis already submerged in the water. Also, these pumps operate very quietly as the water absorbs the noise. They are also more efficient as they do not require a lot of energy to suck in the water as they are submerged within.

There are a few disadvantages with submersible pumps as well. The seals of the pump can become corroded with time and when that happens, water seeps into the motor, making it useless. It must also be noted that these pumps are a bit difficult to repair.

Submersible tank pumps are designed to pump water upwards through the top of the roof. They are generally used in underground tanks where water needs to be pumped up to the roof surface.

Submersible pumps can be installed in above-ground tanks as well, however, you need to keep in mind that the rainwater will be plumbed in from the top. Also, if there is a need to directly access water from the tank, a tap can be installed or you can also choose to connect the rainwater to nearby taps.

It has to be made sure that the submersible pipe is fully submerged in the water because when the pipe is surrounded by water it helps it to cool the motor. If the pipe is out of the water, then it can overheat.

Some of the most common types of Submersible Pumps are –

· Bladder Pumps

· Well Pumps

· Borehole Pumps

· Grinder Pumps

· Fountain Pumps

· Utility Pumps

When properly maintained a submersible well pump can have along with with a lifespan of up to 15 years. It is also recommended to use the best submersible pipe for impeccable performance. At Utkarsh India, we are one of the leading manufacturers of Column Pipes that are ideal for the smooth functioning of submersible pipes. They are designed with square threads to provide smooth fitment /re-fitment.

What Are The Different Applications And Benefits of UPVC Pipes and Fittings?

The term UPVC stands for Un-plasticized Polyvinyl Chloride which shows strong resistance to chemicals and harmful elements of nature. UPVC pipelines are ideal for solving the plumbing needs of commercial and residential properties.

As metal pipes react with several elements of nature, these are not suitable for plumbing applications. These pipes are prone to rust and corrosion. That is why; the supplied water remains safe from impurities wherever a UPVC pipeline system is installed.

Seamless the flow of clean and safe water is a necessity irrespective of the region and the type of properties. The industry has been experimenting with different materials to find the most suitable raw material that ensures a safe water supply.

The invention of UPVC pipes has revolutionized the plumbing industry bringing solutions to several issues associated with metal pipelines. Let us explore UPVC pipe’s various applications and benefits to understand the immense significance it carries across the plumbing industry.

Applications of UPVC pipelines:

· UPVC pipes are used to fulfill plumbing needs across water supply systems. Besides, these are used for Tubework casting and manufacturing raising mains for hand pumps as well.

· In chemical industries, it is used for transporting chloride and other chemicals.

· UPVC is used as ventilation pipes for disposing of corrosive gases from washrooms.

· In the electric industry, UPVC is used for manufacturing electrical conduits.

· For agricultural purposes, it has extensive use in irrigation.

· The crude oil pipeline is made of UPVC as well as it prevents corrosion within the pipeline.

· The sewer system is manufactured out of UPVC pipes too.

Related Blog: Difference Between CPVC and UPVC Pipes

Benefits of UPVC pipelines:

· As a material, UPVCs are very lightweight. Hence, a low amount of shipping and labor charges are required to transport.

· UPVC pipes are budget-friendly and can be installed following a hassle-free process.

· These pipes have anti-corrosion properties which resist chemicals to react with the material. As a result, the water or gas remains unchanged inside the pipeline.

· Due to low thermal conductivity, UPVCs are highly energy efficient. It has flame retardant properties that do not support combustion.

· UPVC pipes are UV resistant, hence can be easily installed outside the building without worrying about the outcomes.

· They are completely eco-friendly and can function both in extreme cold and hot temperatures.

· Being antimicrobial, these are completely safe to carry drinking water as well.

UPVC pipes come with multiple benefits in various applications. They are not only cost-effective but also last longer than any other pipeline materials. These pipes neither need high maintenance nor require a complicated installation process. As UPVC pipelines come with a package of benefits across different application areas, these are preferred by industry professionals worldwide.

Factors To Consider When Looking For HDPE Pipes

High-Density Polyethylene pipes or HDPE pipes and fittings are widely preferred for a plethora of industrial applications. They are recognized for their strength, durability, chemical and corrosion resistance, and minimal leak rate. These pipes are used in a number of applications which include pipeline rehabilitation, sewer piping systems, slip lining, and geothermal applications among others.

When it comes to choosing the best HDPE pipes manufacturers in India, it is quite a difficult task as there are so many of them. Choosing the best out of it for your needs is a complicated and time-taking deal.

Here we have listed some of the factors that you need to consider while choosing the best HDPE pipe manufacturer or supplier.

Let’s take a look.

Understand your purpose – HDPE pipes are used for several purposes and so before looking for a manufacturer or supplier, you should know exactly where you want to use them. You should also know what dimensions you need and the number of pipes you need for your purpose.

Understand the product and its market – You must be well-informed about the market and keep an eye on the changes and updates taking place in the market. You should also understand the technology that is used to manufacture HDPE pipes and how that technology is evolving. This will help you to grab the best deal in the market.

Related Blog: Uses And Advantages of HDPE Pipes

Market reputation– Needless to mention, reputation is something that defines the image of a company. When it comes to choosing an HDPE pipe manufacturer in India, the experience and the reliability of the manufacturer matter a lot. You must check the experience of the manufacturer and also check their online comments, reviews, and website to get a rough idea of what their past customers think about the quality of their products and services.

The manufacturing process and other qualities – The manufacturing process and a few other factors determine the quality of the final product. Qualities like high productivity, use of advanced technology, the cost-effectiveness of the product, and customer service largely matters.

Conclusion

These are some of the factors which you must consider while purchasing HDPE pipes. However, if you are planning to purchase HDPE pipes from leading HDPE pipes manufacturers in India, Utkarsh India has got you covered.

We are a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry. Coming to HDPE pipes, Utkarsh India’s HDPEpipes have been tested and proven effective for above ground, surface, buried, floating applications. It ensures a lifespan of 50-100 years and is certified by the Bureau of Indian Standards.

Everything You Need To Know About GI Pipes

What is GI pipe?

GI (Galvanized Iron) pipes are widely used for the purpose of distribution of treated or raw water in rural areas.

When it comes to projects that are larger in nature, GI Pipes are undoubtedly the best choice. This is because they are sturdy, durable, and are resistant to dust and abrasion. GI pipes are also cheap, light in weight and hassle-free to handle and transport.

These pipes are manufactured using mild steel strips of low carbon steel coils. The process involves coating the metal with zinc, which is called galvanization. It is done to protect the pipe from corrosion or rusting. One of the best things about galvanized pipes is that they are highly protected and cannot be damaged even more from corners.

Galvanised Iron pipes play a crucial role

in water supply systems since these pipes are not only galvanised but coated

with a layer of zinc, which makes them resistant to corrosion and rust. The use

of GI pipes for water supply is widespread due to their ability to withstand

the harsh conditions often associated with water transport, making them an

essential component in plumbing networks and water distribution systems.

Here are some of the top Features of GI Pipes

· Higher ductility and longevity

· Anti-rust zinc coating (Galvanization)

· Corrosion-resistance

· Superior bendability and ease of threading

· Easy to weld which ensures rigorous fabrication

Benefits of GI pipes :

· Perfect for large construction projects : GI pipes are undoubtedly the most suitable when it comes to construction projects of large nature like building construction, construction of manufacturing unit or irrigation systems, etc. It is highly preferred in large construction projects because of its durability and is resistant to abrasion and rust.

· Low maintenance cost : Since GI pipes are coated with Zinc, they are known for staying durable for a long period of time due to their sturdiness. Due to this factor, these pipes are quite cheaper in the long run. These pipes are resistant to corrosion and the so the chance of leakage is also minimal. GI pipes maintain their properties for a considerable time, thus ensuring less maintenance.

· Low-cost piping solution : It is needless to mention that galvanization is the most effective and cheapest method of protecting steel or iron. The process of galvanization does not demand much labour force as so the overall cost of processing is very low. Galvanization is a hassle-free method that does not require any heavy operation.

At Utkarsh India, we stand out as one of the leading GI pipe manufacturers in India. Our GI pipe conforms to national and international standards and is duly approved by all national/International Inspecting & Certification Authorities like SGS, CE, DNV, BVQI, TUV and more.

If you are looking for superior quality GI pipes, then we have got you covered.

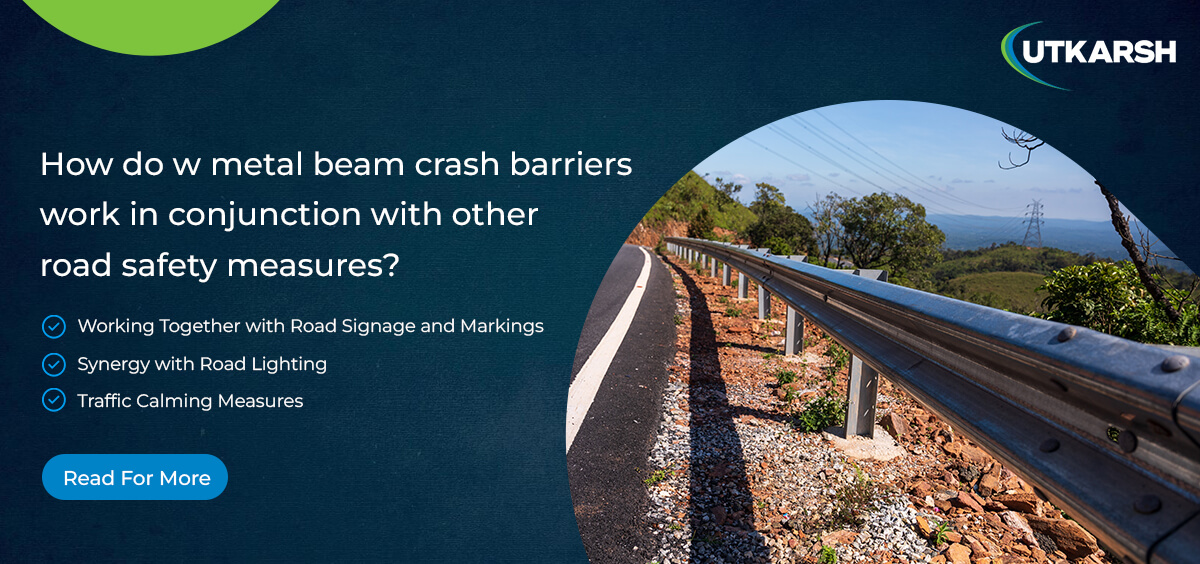

Crash Barriers Its Role In Our Society

Overview

It is needless to mention that road technology is evolving at a fast pace to facilitate smooth driving, thereby significantly reducing travel time. However, we all have also heard of news or even witnessed accidents that are primarily caused due to reckless driving.

We all have seen crash barriers installed on several roadsides. They are quite common nowadays as they serve as a safety measure by protecting the drivers and anyone in the vicinity from facing life-threatening accidents.

They are installed to prohibit the entry of vehicles into certain dangerous areas. The effectiveness of it has led the Government of India has installed safety crash barriers in most of the roads and highways.

Crash barriers have made some significant contributions towards reducing road accidents in India. These objects which might not look so important act as guardians and stop the vehicles from entering into a danger zone.

Here is an example to elaborate on how important crash barriers are. Suppose if a vehicle enters on the wrong side of the road by mistake from where traffic is coming from the opposite direction. This will lead to a collision and a collision of that sort will not only pose a threat to the life of the drivers and the passengers of those vehicles but is also very dangerous for all the surrounding vehicles.

Related: All you need to know about the different types of crash barriers

Now coming to the main question, how Crash Barriers help to reduce the damage?

When a vehicle collides with a crash barrier, the energy of the collision is spread across a wider area which significantly reduces its impact. It absorbs the energy to lower the impact of collision and ensure minimal damage to lives. It must also be noted that as compared to other road safety equipment, crash barriers are much cheaper, are easily available, and can be easily installed.

The best quality crash barriers are made up of sturdy corrugated steel that is capable of providing solid protection against the damage that a heavy vehicle can cause.

Utkarsh India - The leading Crash Barrier manufacturer in India

Being such an important tool concerning road safety, it is necessary to make sure that the crash barriers are of superior quality and arepurchased from a premier crash barrier manufacturer in India. Utkarsh India is one of the leading and most reputed crash barrier manufacturers in Indiaengaged in the manufacturing of a wide range of Metal Beam Crash Barriers andcomponents conforming to Indian, American, European and other internationalstandards. We deal in all types of W Beam Crash Barriers, Thrie Beam CrashBarriers and associated components and anchorage systems.

Our stringent quality control system and finestraw quality materials sourced from brands like SAIL, TATA and Hindustan Zinc hashelped us achieving to rank on top.

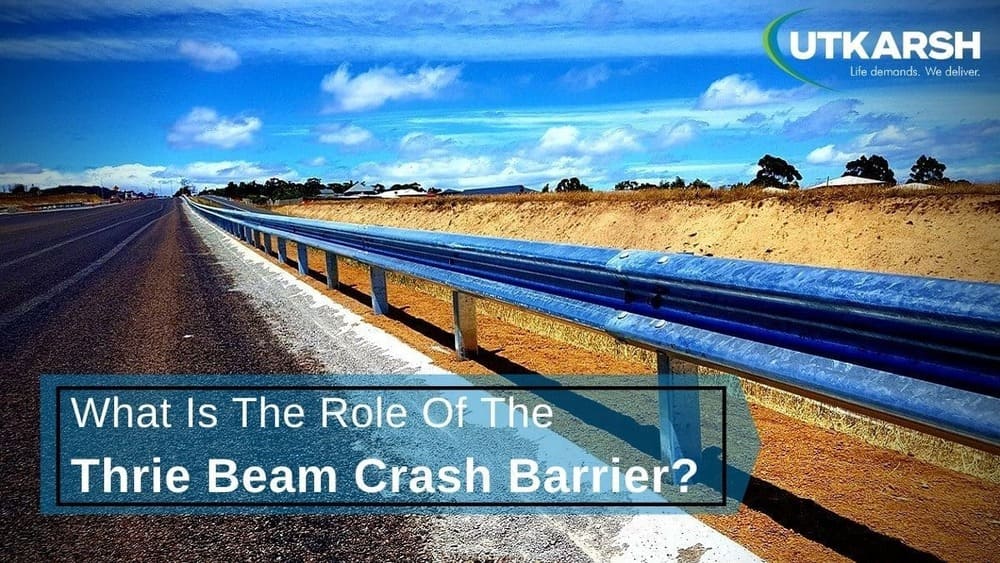

All About A Thrie Beam Crash Barrier And Its Specifications

The importance of a metal crash barrier will never be realized until it someday saves our life.

They are created to prevent major accidents when vehicles lose their balance and run off the road or roll down high embankments. In the unfortunate event of an accident, a metal crash barrier contains, redirects, or absorbs the impact energy of the hitting vehicle and guides the automobile back on the road. Consequently, the severity of the accident, damage to the vehicle as well as the barrier, and the force experienced by the vehicle occupants is minimized to a tolerable limit.

A Metal CrashBarrier is installed in accident-prone locations such as highways, flyovers& bridges, rocky areas, hilly terrain, high embankments, test tracks in the automobile industry, mass housing complexes/townships, airports, railway stations, and parking lots.

The excellent visibility of a metal crash barrier highlights the limit of safe travel, especially at night or in fog conditions. That is why a metal crash barrier proves to be beneficial for drivers venturing out late at night.

Utkarsh India deals in all types of W Beam Crash Barriers, Thrie Beam Crash Barriers, and related components, as well as anchorage systems.

In today’s blog, we will throw some light on Thrie Beam Crash Barriers - what they are and their specifications. So stay tuned.

What is a Thrie Beam Crash Barrier?

A Thrie beam crash barrier has three waves. Compared to two-wave-shaped products, a three-beam crash barrier has a more durable construction and higher impact endurance.

Now let's have a quick look at some of the typical specifications of a Thrie Beam CrashBarrier -

=> The Thrie Beam Crash Barrier comprises a steel post and a 3mm thick rail element.

=> The steel post and the spacer are 75mm x 150mm and 5mm thick.

=> The rail sits at 85cm off the ground and is driven into the ground to a length of 1150 mm.

=> The design conforms to the Indian (MORTH - Ministry of Road Transport and Highways), American (AASHTO M180), Euronorm (EN 1317 - 1&2), Indian Road Congress (IRC) specifications.

=> Manufactured using the Cold Roll Forming Technology with multiple roll forming stations ensuring greater strength due to grain reorientation as compared to the normal press-formed sections.

=> Raw Material used is ST - 42/IS 5986 FE 410/510-grade steel sourced from leading trusted brands like SAIL, TATA, and Hindustan Zinc

=> All the steel components and fasteners are galvanized by the hot-dip process of high-grade zinc coating (550 GSM minimum)

Conclusion

We at UtkarshIndia take pride in being the go-to supplier for leading infrastructure and EPC contractors. Hence, we very well understand our responsibility to manufacture nothing but the best quality and the most durable crash barrier systems.

While our Thrie Beam Crash Barrier meets the industry standards and certified specifications, they are customizable as per the customer requirements to meet the needs of almost any project.

If you want to avail of our exclusive range of metal crash barriers or have any questions to ask, feel free to contact us.

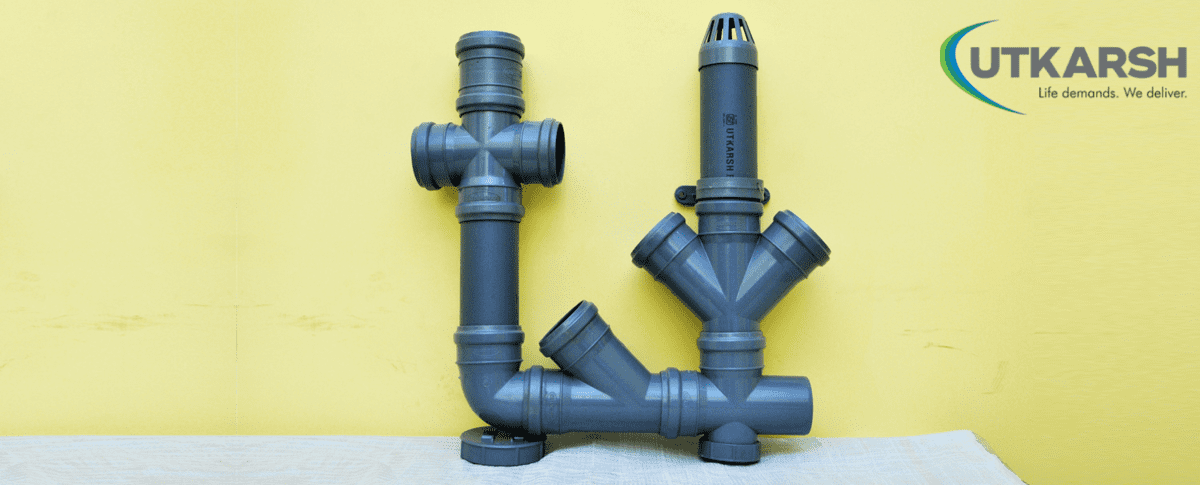

How Are PVC Pipe Fittings Made?

PVC as a material

Also known as PolyvinylChloride, PVC is one of the most common thermoplastic polymers used all over the world. It is naturally white and very fragile plastic before the addition of plasticizers. PVC is generally produced in two forms a rigid or unplasticized polymer and another as a flexible plastic. Industries such as plumbing, water supply, sewage, and agriculture utilize rigid PVC across different functions. Flexible PVC is commonly used for construction purposes to provide insulation on electrical wires or in flooring for homes, hospitals, schools, and in other sterile areas where the environment is a priority.

Characteristics of PVC

Some of the significant properties of PVC are:

- Density - PVC has a specific gravity of around 1.4 and is considered to be the densest plastic.

- Economics – PVC is cheap and readily available in the markets.

- Strength – PVC possesses excellent ductile strength.

- Hardness – PVC in rigid form grades well for hardness and durability

PVC pipes are one of the most universal and versatile types of plastic piping, serving a multitude of applications in various market sectors all around the world. PVC pipes are extremely strong and durable when compared with other piping materials and also prevent corrosion which makes them the ultimate choice for water supply and a manifest for the sewer system in big cities around the world. Economical and robust, these pipes come in various sizes with a wide range of available pipe fittings that are used for both warm and cold-water applications conditional to different types of PVCvariants.

How are PVC Pipes made?

PVC pipes are made by extrusion of raw material PVC, and thereby following the same step of typical pipe extrusion the process mentioned below :

- Feeding of raw material tablets / powdered into the PVC twin screw extruder.

- Melting and heating in numerous extruder zones.

- Extruding further to shape into a pipe.

- Cooling the shaped pipe.

- Finally, cutting the PVC pipes to the desired length.

These are a similar manufacturing procedure for most plastic piping; however, PVC pipes have fundamental features that possess additional characteristics and challenges to pipe manufacturers both in terms of production and market positioning of their products.

Related: Highlighting The Difference Between CPVC and UPVC Pipes

PVC fittings are made from a material known as Polyvinyl Chloride. PVC fittings are manufactured by heating plastic pitches and the molten pitches are set to create desired shapes and sizes. The PVC fittings and pipes are widely used for various reasons like irrigation purposes, building, construction, water supply, sewage management, and many other modes for a requirement.

Description and Application of PVC Fittings

Below is a list of the most commonly used PVC fittings available as follows:

- PVC fittings used as Tees – PVC tees are three-end fitting; it allows a link to be split into two separate lines with a 90-degree connection. They are popularly used for PVC structures.

- PVC fittings used as Elbows – PVC elbows are available in 90-degree angles and 45-degree angles. These are used for redirecting pipelines by bending them into the desired directions.

- PVC fittings used as Crosses – PVC crosses are fittings that are used for connecting four sections of the pipe. They have four slip connection that meets at 90-degree angles forming a plus shape.

These are the description and applications of the three most commonly used PVC Fittings in the markets.

For more information regarding PVC fittings and pipes, contact Utkarsh India Limited a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry at https://utkarshindia.in/.

Best Quality PVC Casing Pipe for Domestic Borewell

Polyvinyl chloride pipes also known as PVC pipes have become the ultimate choice for borewell. We at Utkarsh India Limited as being one of the leaders in the pipe manufacturing industry provides our customer with a variety of range of PVC casing pipes such as casing medium, casing shallow, and casing deep pipes as per the requirement of the customer in different depth of borewell developments. Considered among the best PVC casing pipes for borewells, we produce PVC casing pipes that have high superiority threaded joints and have anti-corrosive properties.

Why should you choose PVC casing pipes for domestic borewells?

Perfect for various Plumbing applications – PVC casing pipes can be used for various plumbing purposes because they can easily maintain the hydrostatic collapse pressure, hence making them an ideal choice for borewell projects. These pipes also can withstand changing water pressure and harsh weather conditions. It is ideal for irrigation, domestic and industrial applications, the PVC casing pipes for domestic borewell are a better alternative to cement, asbestos, and SS pipes. In addition to that these pipes are resistant to corrosion from violent chemicals present in the soil.

Acts as an Insulator - PVC casing pipes are non-conductive to electricity, hence eliminating the chance of electrochemical reactions. Further to that these pipes provide good resistance to chemicals and are immune to electrolytic and galvanic erosion. These pipes are safe to be applied to alkaline, acidic, dry, or wet conditions without any requirement for protective coating.

Superior durability – Unlike conventional metal pipes, PVC casing pipes are corrosion resistant. In addition to that best quality PVC casing pipes do not react to harsh industrial chemicals. Hence PVC casing pipes last longer than metal casing pipes. Their reliability and durability have made them the ultimate choice for all borewell developments. Following that PVC casing pipes are versatile as well.

User Friendly – Installation and Usertransportation are the main matter of discussion when it comes to choosing the best PVC casing pipes for borewell projects. PVC casing pipes have considerably less weight when compared to metal pipes or metal piping materials. This helps with easy transportation and better installation of PVC casing pipes without much hassle. PVC casing pipes come in various ranges which provides the customer with an advantage to fulfill their requirements following their borewell project. The lightweight PVC casing pipes ensure lowering the cost of installation, maintenance, shipping, and labor.

At Utkarsh India Limited, we offer our customers a wide range of PVC casing pipes that fulfill all the above features from being user-friendly, durable, non-conductive to being the perfect material for various Plumbing applications. Our PVC casing pipes come in various dimensions that meets all the chemical properties as per different testing results such as density test, resistance to external blow at zero-degree Contest, effect on the water test, Vicat softening temperature test, and tensile strength test.

For more information regarding PVC casing pipes, contact Utkarsh India Limited a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry at https://utkarshindia.in/.

Difference Between GI And MS Pipe

MS (Mild Steel) Pipes and GI (Galvanized Iron) Pipes are widely used all across the globe for piping and other operations. Both MS and GI pipes are made up of low carbon and zinc protected pipes, used in a variety of industries.

GI Pipes

Galvanized iron pipes are coated in a layer of zinc to

protect the metal from corrosion and increase life expectancy. However, it must

be noted that even with galvanization, corrosion can eventually occur if the

conditions are acidic. They are available in various dimensions and their sizes

vary from 15mm to 150mm. GI pipes are acclaimed because it’s lightweight, low

cost, easy to transport and install as well. These pipes are generally used in

rural areas for the purpose of carrying both raw and treated water.

GI pipes are a popular choice for water supply systems due to their exceptional corrosion resistance. These pipes are constructed from zinc-coated steel, making them highly resistant to rust, even when exposed to moisture and harsh environmental conditions. This corrosion resistance ensures the long-term durability and reliability of GI pipes in water supply, making them an ideal choice for transporting clean and potable water in residential, commercial, and industrial settings.

Related: Everything You Need To Know About GI Pipes

Features of Galvanized Iron pipes:

· Higher longevity and Durability.

· Anti-rust coating and superior finish

· Resistant to corrosion

· Easy to weld and fabricate

Here are the primary uses of GI pipes:

· Water & Sewage transportation

· Structural purposes

· Automotive purposes

· Engineering purposes

· Oil & Gas transmission

· Electric Poles

MS Pipes

Mild Steel Pipes are carbon steel pipes that contain less

than 0.25% of carbon which makes them easy to use and less hard. This ensures

that the pipes stay malleable, ductile and durable. GI pipes can be welded into

various shapes and sizes as per the requirement. Mild Steel pipes are generally

used for Plumbing, Firefighting and HVAC (Heating, Ventilation and Air

Conditioning). These pipes are also coated with paints, varnish or other metals

that protect them from corrosion and makes them long-lasting and resist

critical conditions. The construction industry also relies on the usefulness of

MS pipes as they can be bent and shaped.

Related: A Complete Overview of MS Pipes

Features of Mild Steel pipes:

· High tensile strength

· Made up of low percentage of Carbon

· Can be easily welded

· Budget-friendly

· Long-life

Here are the primary uses of MS pipes:

· General Engineering

· Mechanical purpose

· Structural purpose

· Domestic purpose

· Water steel pipes

Conclusion

MS and GI pipes are widely used all across the globe for pipelines and other operations. While the former is made from mild carbon steel, the latter is coated with zinc to prevent corrosion.

At Utkarsh India, we are leading GI pipe and MS pipemanufacturers in India. We have over 40 years of experience in high-end engineering and manufacturing, we source our materials from the leading raw material suppliers to offer only the best to our customers. If you are looking for superior quality MS pipes or GI pipes, then we have got you covered.

|

GI Pipes |

MS Pipes |

|

Made from steel coated with zinc through galvanisation |

Made from mild steel with no zinc coating |

|

Highly resistant to corrosion and rust |

Prone to corrosion |

|

Less in strength due to zinc coating |

Stronger and more durable |

|

Requires more cost for manufacturing |

Cost-effective |

|

Often used in plumbing and water supply systems where corrosion resistance is crucial |

Wide range of applications, including structural framing, pipelines, industrial machinery, etc |

|

Hard to weld as zinc coating can release toxic fumes |

Easier to weld without the concerns associated with galvanisation |

Contribution of Utkarsh India in Railways

Utkarsh India Limited is a leading supplier and manufacturer in the field of Railway structures in India. We operate on the principle that quality is more than commitment to our customers. Spending more than 40 years in the business as the leading Railway SPS manufacturer we have gained trust by providing high-end engineered products.

We had formed to be the CORE PART I approved vendor to manufacture and thereby supplying various types of products to the Indian Railways which includes portals, masts, gantries, beams, customized structures, and sub-station structures. We offer our customers a wide range of versatile products that are CORE approved, like RSJ Mast, BFB Mast, B Series Mast, TTC Mast, Portal, and SPS.

Here are some of the benefits of the RailwayElectrification Structure:

Increases the speed and efficiency – The Railway Electrification Structure will help to induce the speed and efficiency of the existing trains. By using Railway Electrification Structure, the trains will move faster, hence allowing them to pull more loads or coaches, as compared to the diesel engines.

Cost-effective – Railway Electrification Structure lead to a huge amount of cost-saving as the electric locomotive would engage less amount of money than diesel engines.

Why Utkarsh India Limited is the first choice for Railway Electrification Structures?

We at UtkarshIndia have two plants of 12.5 meter, which provides a Long Hot DIP Galvanizing facility by using Special high-grade Zinc offering a purity of 99.995%. We offer our clients tower-wise bundling to facilitate them at the erection site.

We take raw materials from reputed brands like SAIL (Steel Authority Of India Ltd) and Hindustan Zinc.

Utkarsh India Limited imbibe a group of approved welders along with all the necessary equipment that are required for welding SPS for Railway Electrification structure or any related steel structures for the Railway.

We have a team of designers and we are equipped with the latest hardware and ERP system also known as the Enterprise Resource Planning system.

Certifications:

We at Utkarsh India Limited were certified as the winner with Rail and Metro Awards in the year 2020 by Rail analysis.

We are also been certified by Central Organization for Railway Electrification (CORE) Jangalpur and Gurap.

These are the lists of certifications that we have received, which have made us more determined in delivering much more qualified products that ensure customer satisfaction.

Besides being the leading manufacturer and supplier in India of SPS for Railway Electrification or any related steel structures for the Railways, we at Utkarsh India Limited also offer our customers various other steel products like Steel Tabular Poles, Street Light Poles, HighMasts, Traffic signals and CCTV Poles, and other related structural solutions.

Reasons To Choose CPVC Pipes For Industrial Water Process

Chlorinated Polyvinyl Chloride is also known as CPVC gets manufactured by chlorinating the PVC polymer. As it gets chlorinated, it obtains some unique quality and chattels like ductility and the capability to withstand extreme weather conditions. Owing to its chlorine content CPVC pipes are excellent with chemical resistance, primarily to acids, alkalis, and salts. It is due to that CPVC pipes are the ideal choice for the chemical process industry. CPVC pipes and fitting are also known to possess an ability to withstand physical and chemical degradation that helps offering longer life.

Here I present you the benefits of CPVC pipes that make them ideal for industrial water process:

Corrosion Resistance: Corrosion is a common and ongoing problem in the industrial field. CPVC pipes and fittings are corrosion resistant and they exhibit superior resistance to both internal and external corrosion and virtually eliminates process leaks and flow restrictions thereby eliminating problems of pipe failure.

Easy to install – CPVC pipes and fittings provide an easy installation process. It can be easily installed by using few simple steps, which include solvent and cementing process. The process creates a highly reliable joint by chemically coalescing the pipe to the fitting. When it gets properly installed, a solvent cemented CPVC joint forms the strongest part of the entire system, offering more strength and durability. In addition to that CPVC pipes and fittings are light weighted and the installation process doesn’t require electricity, which makes them ideal for applications where electricity constantly fluctuates.

Require no or very little maintenance - CPVC pipes and the fitting system require very little maintenance if installed properly. Along with that, the external pipe coatings are not necessary because CPVC pipes and fittings remain unaffected even in the most aggressive soil and weather conditions. Contemplating to the facts a portion of CPVC piping needs replacements, which anticipates an easy repairing without the need for welders or lifting device to hoist the equipment into place.

Greater mechanical strength – CPVC pipes and fittings offer an impressive mechanical strength even at an elevated temperature at which industrial plants often operate. CPVC piping system can bear the extreme temperature of 180-degree F that is 82-degree C. In addition to that CPVC pipes and fittings maintains their pressure bearing capabilities for 50 or more years, which makes them durable and helps them in providing long-lasting performance.

These are the benefits that CPVC pipes and fittings offer to industrial water processing. Along with the above benefits, CPVC pipes and fittings are flexible, bendable, and are considered an ideal material for drinking water transmission.

Steel Tubular Pole Features Applications and Specification

Utkarsh India Limited manufactures steel tubular poles not only to illuminate the pathways but to pave the journey to a brighter future.

The steel tubular poles manufactured by Utkarsh India conform to IS – 2713/80 and comes with the strength and durability to withstand torsional stress, harsh winds and with a perfect tensile strength to take all kinds of shocks, cyclones, breakages, and all other extreme climatic conditions. These poles are known for their strength, durability, ductility, lightweight and low-cost maintenance.

At Utkarsh India Limited, we design steel tubular poles to meet the multipurpose demand of architects and engineers for power distribution, illumination, signage, and other diverse needs and requirements.

Features of Steel Tubular Poles:

Made using high-quality steel,

Easy installation procedure and have low maintenance,

They are highly resistant to corrosion,

They are durable and hence ensure a long life.

Applications and uses of Steel Tubular Poles:

Street Lighting

Traffic signal lighting

Signage

Power Distribution

CCTV surveillance, and

Solar Lighting

Specification of Steel Tubular Poles:

1. 410 SP:

Designation – 1 - 3

Overall length (M) - 7.00

Planting Depth (M) – 1.25

Length of sections:

=> Bottom (M) – 4.00

=> Middle (M) – 1.50

=> Top (M) – 1.50

2. 410 SP:

Designation – 4 - 9

Overall length (M) - 7.50

Planting Depth (M) – 1.25

Length of sections:

=> Bottom (M) – 4.00

=> Middle (M) – 1.50

=> Top (M) – 1.50

3. 410 SP:

Designation – 10 - 15

Overall length (M) - 8.00

Planting Depth (M) – 1.50

Length of sections:

=> Bottom (M) – 4.50

=> Middle (M) – 1.75

=> Top (M) – 1.75

4. 410 SP:

Designation – 16 - 24

Overall length (M) - 8.50

Planting Depth (M) – 1.50

Length of sections:

=> Bottom (M) – 5.00

=> Middle (M) – 1.75

=> Top (M) – 1.75

5. 410 SP:

Designation – 25 - 33

Overall length (M) - 9.00

Planting Depth (M) – 1.50

Length of sections:

=> Bottom (M) – 5.00

=> Middle (M) – 2.00

=> Top (M) – 2.00

6. 410 SP:

Designation – 34 - 39

Overall length (M) - 9.50

Planting Depth (M) – 1.80

Length of sections:

=> Bottom (M) – 5.00

=> Middle (M) – 2.25

=> Top (M) – 2.25

7. 410 SP:

Designation – 40 - 48

Overall length (M) - 10.00

Planting Depth (M) – 1.80

Length of sections:

=> Bottom (M) – 5.20

=> Middle (M) – 2.40

=> Top (M) – 2.40

8. 410 SP:

Designation – 49 - 57

Overall length (M) - 11.00

Planting Depth (M) – 1.80

Length of sections:

=> Bottom (M) – 5.60

=> Middle (M) – 2.70

=> Top (M) – 2.70

9. 410 SP:

Designation – 58 - 66

Overall length (M) - 12.00

Planting Depth (M) – 2.00

Length of sections:

=> Bottom (M) – 5.80

=> Middle (M) – 3.10

=> Top (M) – 3.10

10. 410 SP:

Designation – 67 - 72

Overall length (M) - 13.00

Planting Depth (M) – 2.00

Length of sections:

=> Bottom (M) – 5.80

=> Middle (M) – 3.60

=> Top (M) – 3.60

11. 410 SP:

Designation – 73 - 76

Overall length (M) - 14.50

Planting Depth (M) – 2.00

Length of sections:

=> Bottom (M) – 6.50

=> Middle (M) – 4.00

=> Top (M) – 4.00

12. 410 SP:

Designation – 77 - 80

Overall length (M) - 16.00

Planting Depth (M) – 2.30

Length of sections:

=> Bottom (M) – 7.00

=> Middle (M) – 4.50

=> Top (M) – 4.50

These are the types of Steel Tabular poles we offer. To get more details about our steel tubular poles, click here https://utkarshindia.in/Engineering-Steel_Tubular_Pole.

If you have any queries, please contact us at info@utkarshindia.in.

Does Galvanization Save Time On Fabrication Projects?

When the structure of Mast TTC or steel gets galvanized, it produces a grey matte finish, which blends in well, regardless of the surroundings. When the structure of Mast TTC or steel gets galvanized, it produces a grey matte finish, which blends in well, regardless of the surroundings. This process helps to increase the life span of steel and Mast TTC structures, hence preserving the solidity of it and thereby saving time and money.

How Many Types Of CPVC Pipe Are There?

The piping industry is highly undervalued. The quality, safety, and performance provided by such an industry help to play a crucial part in safeguarding the environment along with the lives of people. CPVC pipes and Fittings produced by Utkarsh India, one of the premier CPVC pipes manufacturers in India; are manufactured using high-quality plasticizers, which helps the pipes with utmost rigidity and provides sturdiness.

What is CPVC?

Features provided by CPVC pipes and Fittings of Utkarsh’s

Types of CPVC Pipe and Fittings

List of CPVC fittings as follows:

Agricultural Applications Of PVC Pipes

Before we turn to the details of the use of PVC pipes in the agricultural industry, let's first recall that India ranks second worldwide in agriculture production, is the world's largest producer of fresh fruits and vegetables, and ranks second in wheat and rice production. All these facts prove that agriculture is of paramount importance in the country as it generates nearly 16 percent of the GDP. Thus, much of the infrastructure and equipment in the agriculture sector is crucial to its efficient functioning.

The agricultural sector relies heavily on drainage and irrigation channels made of PVC pipes and fittings. Rigidly built PVC pipes are essential when the soil is deficient in absorption capacity or when water levels are high due to salinity levels on the land. This is because PVC pipes have a smooth lining that ensures water travels smoothly to its intended destination with a minimum of clogging as compared to pipes made out of similar materials like copper and clay.

With all of that in mind, let us move straight to the core of this blog.

Use of PVC Pipes in Agricultural Industry

Below are just some of the ways to use PVC pipes in your agricultural facility:

PVC Sprinklers

Large-scale water supply systems rely heavily on PVC pipes. They can be mounted aboveground and linked to the main water source and sprinklers. When buried as deep as 10", ¾†PVC pipes make excellent irrigation laterals.

Drip Irrigation

A popular watering method, drip irrigation involves punching holes through the hose to control the flow of water. Its popularity stems from the fact that it provides sustainability to your agricultural facility by conserving water. This framework is perfect for little-to-medium-sized gardens and enables each plant inside that region to get an unfaltering stock of water delivered to the roots. Using PVC pipes in this system is feasible because they're flexible, so they won't tear once they've been punctured.

You May Like: Best Quality PVC Casing Pipe for Domestic Borewell

Vertical Garden

There are various ways of forming a vertical garden using different sizes of PVC pipes. A small PVC pipe with an irrigation line is inserted inside a larger PVC pipe with the pot of soil and the plants.

Hydroponic garden

Water is supplemented with nutrients to support seedling growth in hydroponic gardens. It is also referred to as an active system and is a type of hydroponic farming that reliably produces more while conserving water. PVC pipes hold plants in mid-air, and water containing nutrients flow through the pipes continuously. Since PVC pipes are lightweight and lack toxicity, they are apt for this system.

You May Like: What makes HDPE Pipes better for Agriculture and Irrigation Application?

Final words

Many agriculture facilities utilize agriculture PVC pipes and fittings as water delivery systems. Their corrosion resistance and ability to stabilize UV rays make them an ideal choice for any farming operation. PVC pipes play a crucial role in large-scale agricultural facilities because they make irrigation more sustainable and efficient. Small agricultural spaces or even home gardens can be irrigated using PVC pipes.

4 Different Varieties Of Transmission Towers With Respect To Their Applications

A transmission tower supports every high voltage transmission line. A transmission tower (also known as a power transmission tower, power tower, or electricity pylon) is a tall structure (usually a steel lattice tower) used to support the high-voltage conductors of overhead power lines. The transmission towers differ from conventional power poles since they transport bulk electricity from multiple high voltage lines over long distances as opposed to single poles that provide local delivery.

Types of Transmission Towers

In terms of their technical background, the following is a list of transmission tower types.

Let's take a look at each of them one by one:

Suspension Towers

High voltage suspension towers are designed to withstand only the weight of the conductor when they are positioned in a straight line. Conductors on suspension towers can be held in place by I strings, V strings, or a combination of both. Suspension transmission towers run on straight-line routes where there is less than a 5-degree deviation in angle.

Transposition Towers

They are most common in three-phase line systems and are often used to support and maintain long transmission lines where the weight in the centre of the span puts significant stress on the structure. A transposition tower is supported by a body, a cage, and a peak. Conductors and lines are positioned at a distance that prevents contact between the cross-arms of the towers.

You May Like: How Does Railway Electrification Work?

Tension/Angle Towers

They support the directional change of transmission lines in turning points where the angle of deviation is more than 5 degrees. The tower is reinforced with anchors to counteract pressure exerted against the angle. The transmission line that connects two angle towers is called a section. The length of the section depends on geographic location, easements, possible placement possibilities, and the ultimate destination.

Special Towers

Custom towers are built when conditions dictate a significant change in angle or when a substantial amount of additional support is needed based on environmental factors. Among the factors that affect transmission tower construction are heavy wind, porous soil, freezing rain, and others. In addition, these towers are used in areas involving long-span river crossing, valley crossing, power line crossings above existing lines, power line crossings below existing lines (Gantry type structures), tapping existing lines, unique termination towers and the like.

Final words

Power outages and blackouts disrupt people's everyday lives and mess with the productivity of industries dependent on electricity since power transmission is compromised. Thus, proper transmission towers need to be in place to prevent power cuts and faulty transmissions that hamper a country's economy.

Utkarsh India manufactures Powergrid approved Transmission Line Towers ranging between 66 kV to 765 kV. Our full-range-cum-diverse product basket comprises CHT/VHT/UHT HVDV to AC (single, double, multi-circuit) transmission towers suitable for Twin, Quad and Hex conductor configuration to accommodate both AC lines and DVDC lines. Our impressive client portfolio includes Airtel, Idea, BSNL, Reliance, Vodafone, etc.

If you are someone who values quality before anything else, place your order with Utkarsh India now while there is still time.

Here Are Some Various Types Of High Mast Poles

Truth be told, nocturnal driving is more hazardous than daytime driving. Even when a vehicle's headlights are on, visibility is reduced. Furthermore, dark railway yards tend to be crowded with miscreants or trespassers, becoming a hotbed of criminal activities.

Therefore high mast lighting solutions, also known as HMLs, are typically used in large public or commercial areas like warehouses, shipyards, railway yards, highways, parking lots, stadiums, etc. High mast lighting poles are an effective solution for improving the illumination of dark and concealed areas, ensuring maximum safety.

One of the renowned high mast light pole manufacturers, we at Utkarsh India, believe that it is our responsibility to inform our audience about the different types of high mast poles and their uses.

So, let's get down to business without further delay.

Stadium Mast: As outdoor sports and high-definition sports television broadcasts grow in popularity, sports venues need to be equipped with high-quality lighting. Fans and players alike benefit from optimum lighting. It is critical that players see clearly as the game picks up speed. As fan expectations rise, so do ticket prices, and the quality of the broadcast and viewing experience must always exceed the standards of high-definition broadcasts and technologies. Therefore, stadium masts are installed in stadiums, fields, and playgrounds to provide lighting during the evening hours.

Flag Mast: Whether you raise your flag once or raise and lower it each day, a flag mast is essential. Whether it is a government facility, college or university campus, sports venue, commercial enterprise, park or even for personal use, a custom-engineered flag mast that is easy to use, backed by decades of pole design and manufacturing experience, is indispensable. Tapered flag mast designs reduce wind-induced damage and prolong the life and durability of the mast.

You May Like: Applications and Benefits of Using High Mast Lighting

Signage Mast: If you run a business where your customers have to find your location, such as a gas station, a grocery store, or a repair shop, signage masts are the best way to attract customers and highlight your brand. Installing signage masts near high traffic roadways provides optimum visibility and leaves a lasting impression on customers' minds.

Solar Mast: In light of non-renewable resources' limited and scarce nature, it is our responsibility to conserve them. Solar high mast provides light to a wide area without using conventional electricity or requiring costly electrical networks. It is advisable to use solar masts in areas where electricity is not readily accessible or where saving electricity is the highest priority. Solar masts are more reliable than conventional lighting systems since they are shock, vibration, and impact resistant.

High Mast Lighting Systems: High mast lighting is a type of site light fixture raised high to minimize ground-level obstructions and create uniform illumination across a massive space. The use of high mast lighting systems minimizes shadows that may result from using shorter poles. High mast lighting plays an exclusive role in facilitating night-time travel and transportation, citizen engagement in social gatherings and sports/recreation activities, around-the-clock industrial production, safety and guidance of traffic, and security of commercial, residential and public facilities and properties. Utkarsh India is among the leading high mast light pole manufacturers.

Final Words

The focus of every order, no matter how big or how small, whether it's a standard product or a custom product, will always be on delivering quality. As your go-to high mast light pole manufacturer, we promise to provide our products before the deadline and in accordance with your specifications.

We shall be glad to provide further details upon your request, so feel free to get in touch with us.

Specifications And Uses Of GI Pipes

GI Pipes or Galvanized Iron Pipes are widely used for the purpose of conveying raw water and distribution of treated water in many rural water supply schemes, where the requirement of water is limited.

It is dipped into zinc for protection against corrosion and they are manufactured using mild steel strips of Low Carbon Steel Coils. The steel strips are passed through a series of fin rolls to achieve a circular shape. The slit ends of the strips are then welded together by passing an electric current of high frequency across the edges. The welded steel pipes are then passed through sizing sections where any dimensional issues are corrected and are then cut into desired lengths by automatic cutting machines. Lastly, these are pressure tested for any leaks randomly.

GI pipes are categorized into light, medium and heavy. Here is how you can determine –

• Light (Class A) - Marked in yellow color for identification.

• Medium (Class B) - Marked in blue color for identification.

• Heavy (Class C) - Marked in red color for identification.

You May Like: Everything You Need To Know About GI Pipes

Here are some of the top uses of GI Pipes –

• Water and Sewage transportation

• Structural purposes

• Automotive purposes

• Electric poles

• Oil and gas transmission

• Engineering purposes

You May Like: Difference Between GI And MS Pipe

Features of GI pipes –

• Superior durability and sturdiness

• Greater resistance to corrosion

• Easy fabrication and weld consistency

• Protected by anti-rust zinc coating

• Greater bendability

What makes Utkarsh India one of the leading GI pipe manufacturers and suppliers in India?

At Utkarsh India, we have over four decades of experience in the field of agriculture and domestic water piping, we manufacture superior quality GI pipes that conforms to national and international standards and are duly approved by all National/International Inspecting & Certification Authorities like SGS, CE, DNV, BVQI, TUV and more.

Our superior quality Galvanized Iron Pipes are available in diverse sizes and thicknesses following the IS, BS and ASTM specifications and we also follow strict testing parameters of Mass of Zinc Test, Uniformity test and Adhesion test for best quality output and for customer satisfaction. We also carry out a 7 bath technique for galvanizing.

So if you are looking for superior quality GI pipes in India, then we at Utkarsh India, have got you covered.

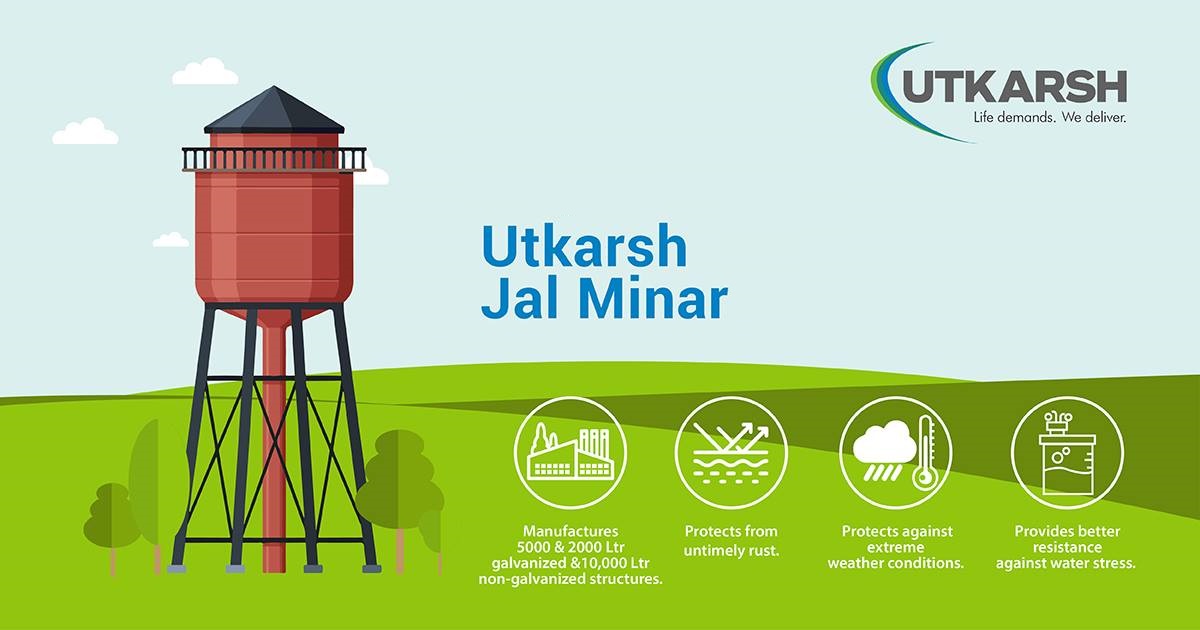

Discover All There Is To Know About The Jal Minar